Trendlines: Prolonged trough for China may be felt far and wide

23 June 2024

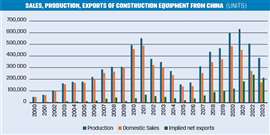

The Chinese construction equipment market has problems. After an enormous stimulus spending spree in 2020 and 2021, sales of equipment more or less halved in 2022 and halved again last year. Off-Highway Research believes this year will see the bottom of the cycle, but it will also be a slow journey back to health thereafter.

Source: Off-Highway Research

Source: Off-Highway Research

As well as stimulus-driven boom and bust, the domestic industry has to cope with enormous bad debt problems in the real estate sector, the scaling back of road building work, and further debt problems for many provincial governments. The short list of positives include the mining segment and railway construction.

How the Chinese industry is reacting to this has implications around the world.

A record number of construction machines was exported from China in 2022, while 2023 was the first year ever that exports were higher than domestic sales. This figure not only includes indigenous OEMs, but also the numerous international manufacturers which have significant production bases in China.

China’s leading OEMs have had ambitions to be global giants in the industry and this predates the current domestic issues by years if not decades, but the current woes have certainly given more impetus to the development of export markets.

A lack of brand recognition, establishing residual prices and building strong distribution networks will all take time for China’s OEM’s to establish. However, some significant strides were made during the pandemic when more entrenched manufacturers had supply chain and delivery headaches, but Chinese OEMs had excess capacity due to the start of the home market collapse.

More electrics?

Across the machine types we cover, Off-Highway Research data shows the total world market for electric construction machines was 6,000-7,000 units last year (that is to say machines which have traditionally been diesel-powered, not equipment like small scissor lifts which have a long history of electrification). Some 75 per cent of those sales were in China, and an even higher proportion of electric machine production was in China, mostly by indigenous OEMs. There are at least 30 producers of electric construction equipment in China – some well-known names in the industry world, but many which are new to the sector and which have entered from on-road applications.

Chris Sleight, managing director, Off-Highway Research.

Chris Sleight, managing director, Off-Highway Research.

Electric machines are likely to be at the forefront of Chinese OEMs’ renewed push into overseas markets. They have first over advantage and less-developed distribution networks are not such a hindrance for machines with lower parts counts, fewer moving parts and lower service requirements in general.

Whereas a rule of thumb in Europe or North America for the last few year has been that the electric version of a machine is around 2-3 times the cost of the traditional diesel version, a 5 tonne capacity electric wheeled loader cost the same as the diesel equivalent (about a 230 horsepower machine) in China last year. This year the electric versions could be cheaper.

The argument in favour of electric equipment to date has been that although the purchase price might be a lot higher, the customer wins in a few years because of the lower Total Cost of Ownership (TCO). If the purchase price now becomes compelling growth in electric equipment sales could rise extremely steeply and the barriers will start to come down to practical issues around charging times and charging infrastructure.

One important point around wheeled loaders and why electrification has already moved quickly in China (penetration was close to 10 per cent last year) is that they have a lot of applications in waste management, mining and quarrying, where infrastructure is in place and there is access to grid power. That removes the big hurdle in a greenfield project – where do you plug it in to charge?

CONNECT WITH THE TEAM