Isuzu’s range of open power units for generator sets

04 August 2023

In the not-far-distant past, original equipment manufacturers expected a supplier to deliver its product, at which point the manufacturer would take it and engineer it into a machine. But over the last decade, OEMs have leaned on their suppliers to provide more than just their product. Now, the demand is for the supplier’s component to be engineered into a system that the OEM can basically plug and play.

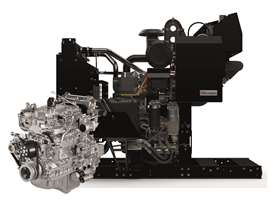

Isuzu has developed a range of pre-validated power units for power generation applications based on its 4H (above), 4J and 6H diesel engines. (Photo: Isuzu)

Isuzu has developed a range of pre-validated power units for power generation applications based on its 4H (above), 4J and 6H diesel engines. (Photo: Isuzu)

With an eye toward that trend, the PowerTrain Division of Isuzu Motors America, has developed a range of open power units for generator set applications that are more than 90% pre-validated, enabling power generation system packagers with an essentially “drop-in” power generation product.

“What normally happens for a new power unit installed in a customer machine is a series of tests are run in the application,” said Kevin King, executive manager, Product & Application Engineering, Isuzu Motors America, Powertrain Division in Plymouth, Mich. “We check several parameters to make sure that the engine power unit is correct for the application. These parameters are compared against a set of criteria to make sure that the power unit is going to operate properly in that application.

“With a pre-validated power unit, we can take care of a lot of the testing that’s needed before it gets installed into the customer application, so they may have to do very little or no application testing depending on the engine control panel used. Since the customer won’t have to go through a long series of testing to validate the unit, this will save them a lot of engineering time.”

The units are based on Isuzu’s 4J, 4H and 6H inline engines operating at 1800 rpm. The 4J is a 3.0 L four-cylinder diesel rated 95 hp (70.8 kW), the 4H is a 5.2 L four-cylinder diesel rated 171 hp (127.5 kW) at 1800 rpm, while the 6H is a six-cylinder 7.8 L engine that offers a maximum rating of 260 hp (194 kW).

The power units typically include the engine, engine radiator and fan, dual element air cleaner, oil filters, generator cross member mountings and elastomeric isolators for the engine and generator. The power unit is mounted to a skid base that incorporates integrated pockets for lifting with a forklift.

The power units are compatible with – depending on the specific unit – Stamford, Marathon and Mecc Alte generators – and control options include Cattron’s Dynagen TG410 panel or Isuzu’s own RedTECH digital controller.

The power units also incorporate subframes for mounting the engines’ emissions control components, including selective cataltic reduction (SCR) systems and diesel emissions fluid (DEF) tanks. The aftertreatment is mounted above the flywheel to provide sufficient clearance for the generator.

“It’s a complete package,” King said. “Our team designs all the accessories that attach to the engine – the skid base, engine mounts, cooling package, intake and exhaust systems, wiring harnesses and control panel. We do all that engineering and then go through all the validation testing.

“So a customer can buy this, install it and have it operational in a short period of time.”

CONNECT WITH THE TEAM